Annual bridge inspection using 3D models

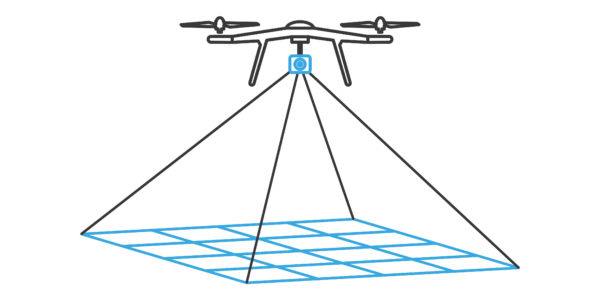

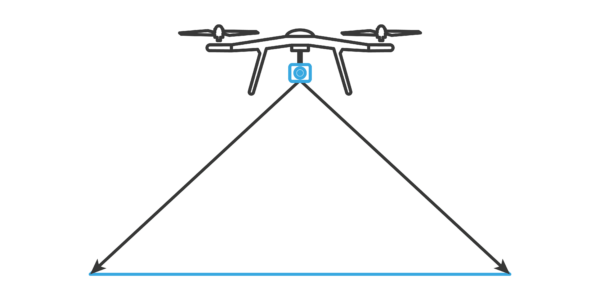

Eyefly uses a Phase One iXM-100 to fly closer to Buggenum Railbridge and achieve a resolution of nearly 1mm with an image footprint of 12m x 9m from a flight height of 10 meters distance. This 3D Bridge Inspection technique allows data is used to create and provide a 3D mesh and inspection platform of the structure for the required annual bridge inspection.

Image: One can identify and zoom, with high-resolution images onto areas of the bridge that require maintenance – Eyefly 2020 ©.

Our business has grown since we started with Phase One cameras as we are able to provide our customers with all the data that they need in one flight. The result is satisfied end-users who come back as we can provide them with more details and better accuracy than we could with lower resolution sensors

Eyefly acquires high-resolution aerial data in congested areas and controlled airspace

Dutch company Eyefly is a fully certified drone operator in the Netherlands that has obtained papers regarding the commercial use of drones and additional certificates for flying in congested areas and controlled airspaces. The company focuses on performing inspections and mapping (2D and 3D models) with aircraft that have been tested by the Netherlands Aerospace Center and registered in the aviation records.

The company offers a specialist level of expertise and skills in infrastructure, construction, geo-information, and surveying. To provide the best results with their existing certified equipment they need to use high-resolution cameras that are ready to integrate. The Phase One Industrial iXM-100 camera easily integrates with their DJI M600 and Freefly Alta UAVs and provides close-to-1mm resolution data, with a large footprint, at a safe enough distance from the object to meet their safety requirements.

Bridge Inspection

Annual maintenance inspection of bridges

An annual maintenance inspection of Buggenum Railbridge is required to identify changes in the structure from year to year. Areas of wear and damage are identified. Areas with the highest changes are seen and given priority.

Before acquiring Phase One drone camera Eyefly faced the challenge of keeping their UAVs at a safe distance from the bridge and still get a resolution/GSD pixel close to 1mm. Lower resolution sensors meant tens of thousands of images with smaller footprints had to be captured over a number of days.

Images were just provided to their clients via a sharing platform like WeTransfer instead of providing a cloud-based model. So many images without the ability to correctly trace back their position made it too difficult, if not impossible, to generate a 3D mesh of the structure.

Inspection via web-based 3D models

Availability of GPS is limited on the underside of the bridge. Images are therefore captured with a large overlap in order for their processing software to provide orientation parameters and position data.

The iXM-100 EyeFly has reduced the number of images enormously and is able to create a 3D model of the entire project for their web-based platform with inspection functionality. This method allows their clients to perform an inspection much more efficiently without losing detail and doing any compromises.

Large footprint without reducing the level of detail

Eyefly company director, Remco Koostra explains “We chose the iXM-100 as it easily integrates with our DJI M600 platform in combination with the Phase One iX Capture Mobile Application.”

“The camera is used on both our DJI M600 and Freefly Alta UAVs. The M600 is used for capturing top and sides part of the structure and the Alta enables us to perform an inspection from the underside of the bridge because of the ability to mount the iXM-100 on top” continues Koostra.

Eyefly uses the RSM 80 mm lens as it has a focus of 10m to ∞ while the RSM 35 mm AF lens is only 30m to ∞. The 80 mm lens enables them to fly closer to the bridge and achieve a resolution of nearly 1mm with an image footprint of 12m x 9m from a flight height of 10 meters distance from the object.

Image: 3D Model of Buggenum Railbridge – Eyefly 2020 ©.

Integrated drone payload

The system includes:

-

- Phase One iXM-100 medium-format camera

- 35mm RSM lens – focus of 30m to ∞

- 80mm RSM lens – focus of 10m to ∞

- DJI M600 PRO drone

- Phase One iX Capture Mobile application

The Phase One iXM-100 camera easily integrates with Eyefly’s DJI M600 UAV and by using the iX Capture Mobile application, full camera control and remote management is obtained.

Contact a Phase One Expert

If you would like to learn more about our Payloads for Drones, our experts are eager to help! Contact Us.

Geospatial

Mapping lava flows during volcanic eruptions in Iceland

Geospatial

The PAS Pana: a 48,800-pixel camera innovated with our customer Surdex

Geospatial

Rebuilding after Hawaii’s wildfire with engineering-grade surveying

Geospatial

Revolutionizing Slovenian urban planning: Phase One’s PAS 880i redefines reality mapping

Geospatial

Imaging solutions combined with AI and 5G – A new approach and promising to assess forest health and detect and monitor wildfires

Geospatial

Phase One Cameras combined with light, fixed-wing aircraft deliver highly efficient LiDAR and mapping missions

Geospatial

Capturing Glastonbury Festival

Geospatial

Breaking barriers to offshore wind energy development

Geospatial

Using aerial oblique images combined with close range UAV (uncrewed aerial vehicles) based data

Geospatial

A change in the future of high-risk, critical asset inspections: fast, effective and safe aerial powerline inspection in a fraction of time and with real cost savings

Geospatial

Using drone technology for Flare Stack Inspection: Getting the smallest details from a safe distance

Geospatial

The Experiences of EyeFly with Phase One iXM

Geospatial

Dam Fine Data: Sub-millimeter-resolution UAV Dam Surveys by Orthodrone

Geospatial

Trimble Inpho – High class photogrammetry with aerial imagery from PAS 280

Geospatial

MapSoft – Multi-sensor Aerial System Improves Urban Development

Press Release

Phase One, Quantum Systems and Trimble unveil groundbreaking survey grade UAV solution with the launch of Phase One P5 camera

Press Release

Phase One Selects Globe Flight as Sales Partner for Drone Solutions in Germany and Austria

Press Release

Phase One ernennt Globe Flight GmbH als Vertriebspartner für Drohnenlösungen in Deutschland und Österreich

Press Release

Remote Vision Named as Swiss Reseller of Phase One Drone Payloads